Oct. 18, 2021

With plastic film as the medium and metal film as the electrode, metal film capacitors are made by winding the previous mentioned materials together (except for laminated structure). The films used in metal film capacitors can be polyethylene, polypropylene, and polycarbonate. In addition to the winding type, there are also laminated type. Polyester film and polypropylene film are more widely used. In this article we will talk about the role of metallized film capacitor and its production control.

The role of metallized film capacitors:

Capacitors of metallized film have a so-called self-recovery effect, that is, when the tiny part of the electrode is short-circuited due to the fragile electrical boundary, the electrode metal around the short-circuited part will cause a larger area to melt and evaporate due to the electrostatic energy or short-circuit current, so as to restore the insulation. Therefore, the capacitor is able to continue to function normally.

The production process of metal film CBB capacitor : 1. Base film; 2. Vapor-deposited metal layer; 3. Slitting; 4. Winding; 5. Zinc spraying; 6. Empowerment; 7. Welding leads; 8. Assembly; 9. Epoxy or vacuum immersion oil; 10. Sealing; 11. Check the packaging.

For regular brands, the details in the process of producing capacitors are under the supervision of strict control personnel. In order to ensure the overall quality, after all, the production quality determines the life of the electronic products produced. Whether it is slitting or winding or welding leads, experienced personnel are required to perform operations. Every single step should be under control, otherwise the capacitor performance cannot be guaranteed.

The production process of metal film capacitors is roughly like that mentioned above, but relatively speaking, there are certain standards. Firstly, the winding technique determines the capacity, and secondly, there is a certain standard for the process of the spraying gold. The more evenly the gold are sprayed, the better. The welding and assembly requirements for the entire capacitor production process are also very high. It is necessary to ensure the effectiveness of welding, but also to pay attention to packaging. It is a wise choice to choose a suitable packaging method according to the needs of different customers.

When choosing metal film capacitors, it is advisable to look for a regular manufacturer. Dongguan Zhixu Electronic Co., Ltd. (also JYH HSU(JEC)) has a full range of varistor and capacitor models with guaranteed quality. JEC has passed ISO9001:2015 quality management system certification; JEC safety capacitors (X capacitors and Y capacitors) and varistors have passed national certifications of the main industrial powers across the world; JEC ceramic capacitors, film capacitors and super capacitors are in compliance with environmental protection indicators. Welcome to contact us for free samples and any questions.

The Charging Speed of Supercapacitors VS Battery

Oct. 18, 2021

Differences Between Varistor 10D 471K and 14D 471K

Oct. 18, 2021

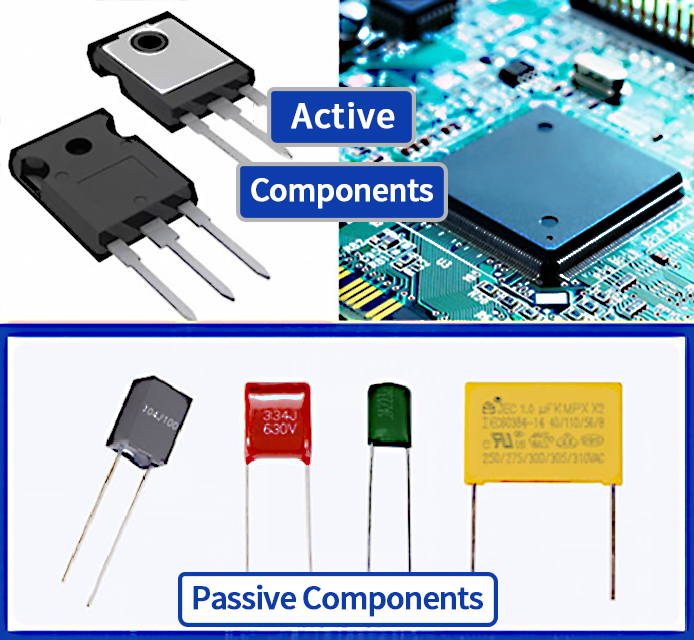

What are Active Components and Passive Components

Oct. 18, 2021

+86 181 2299 5593

+86 18122995593

+86 769 8831 3605

Beside Luchong Bridge, Hou Road, Caibai Village, Daojiao Town, Dongguan, Guangdong, China

Navigation