Mar. 22, 2024

Here are the production processes of film capacitors:

Material Preparation: Select high-quality dielectric materials such as polyimide (PI), polypropylene (PP), polyethylene (PE), polyester (PET), and conductive materials like aluminum (Al) or zinc (Zn).

Dielectric Coating: Apply the dielectric material uniformly onto the conductive material through processes like coating or vapor deposition.

Electrode Formation: Form electrodes using techniques like vapor deposition or sputtering, typically on one or both sides of the dielectric layer.

Cutting and Packaging: Cut the large film into required sizes and encapsulate to protect against external factors.

Electrode Lead Welding: Weld electrode leads onto the packaged capacitor to connect it to circuits.

Quality Inspection: Test capacitance, voltage tolerance, dimensions, etc., to ensure compliance with specifications.

Terminal Processing: Process the welded capacitor terminals for connection with other components or circuits.

These are the main production steps for thin film capacitors, which may vary slightly depending on capacitor type and specifications but generally follow these basic processes.

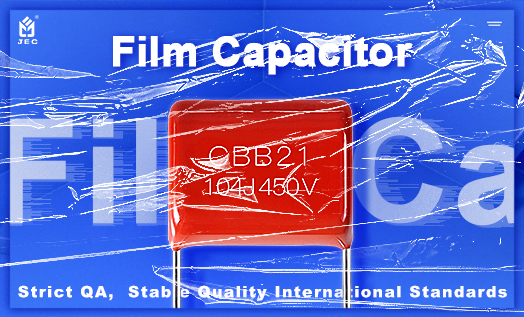

This article is provided by JYH HSU (JEC) Electronics. JEC is a research, development, production, and sales-oriented company specializing in manufacturing and selling various electronic components such as capacitors and resistors.

What Are The Consequences Of Overheating The Varistor

Mar. 22, 2024

The Working Principles and Functions of Film Capacitors

Mar. 22, 2024

The Role of Film Capacitors in Different Applications

Mar. 22, 2024

+86 181 2299 5593

+86 18122995593

+86 769 8831 3605

Beside Luchong Bridge, Hou Road, Caibai Village, Daojiao Town, Dongguan, Guangdong, China

Navigation