Sep. 30, 2022

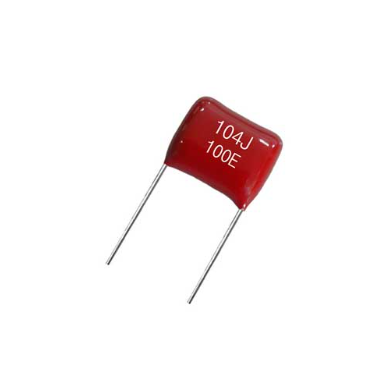

You may not have heard of film capacitors, but everyone in the capacitor industry knows that it is a popular type of capacitor on the market, which uses polyethylene, polypropylene, polystyrene and other plastic films as the the dielectrics, the tin-copper-clad steel wire as the wire, the metal foil as the electrodes, and the electrode and the dielectric wound to form a structure which is encapsulated with epoxy resin later. The film capacitor has good flame retardant performance, and the appearance of the film capacitor is mostly box-shaped, cylindrical, but there are also square-shaped and round-shaped.

According to the different plastic materials that make up the dielectrics, film capacitors are divided into polyethylene film capacitors, polypropylene film capacitors, polystyrene film capacitors and polycarbonate film capacitors. Film capacitors are not very common, but the electronic products you use have their existence. They are the basic electronic components that make up electrical appliances. They are widely used in communication, household appliances, medical equipment, automation equipment, new energy vehicles and many other industries for their high-voltage resistance, long working hours, good temperature characteristics, and stable performance.

With the development of technology level, product update in many industries such as electronics, home appliances, and communications are getting faster and faster, and film capacitors have gained a firm foothold in these industries by virtue of their own advantages and strengths. In the next few years, with the further development of digitalization and informatization, the market demand for film capacitors will grow more rapidly.

At present, the rapid growth of the social population has led to energy shortages, and frequent human activities pollute the environment. In order to solve the problems of energy shortages and environmental pollution, low-carbon environmental protection, green travel, and carbon neutral policies have been continuously introduced. The birth of new energy electric vehicles has solved some of the problems of energy shortage and environmental pollution, and new energy electric vehicles have become a low-carbon and environmentally friendly choice. With the development of the times and the advancement of science and technology, the development of new energy electric vehicles is getting better and better, and the film capacitor as an indispensable component, the demand for it is also growing rapidly, and its development prospect is good.

To purchase electronic components, you need to find a reliable manufacturer first. JYH HSU(JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.) has a full range of varistor and capacitor models with guaranteed quality. JEC has passed ISO9001:2015 quality management system certification. Welcome to contact us for technical problems or business cooperation.

How Is The Leakage Current In Ceramic Capacitors Formed

Sep. 30, 2022

The Self-Healing Aspect of Film Capacitors

Sep. 30, 2022

Why Use Film Capacitors In Analog Circuits

Sep. 30, 2022

+86 181 2299 5593

+86 18122995593

+86 769 8831 3605

Beside Luchong Bridge, Hou Road, Caibai Village, Daojiao Town, Dongguan, Guangdong, China

Navigation