Sep. 24, 2021

Varistor is one of the common capacitors. Varistor can protect the subsequent circuit and protect the circuit from lightning strikes. Some people wonder why varistor would be damaged. Read this article to find the answer.

1) Sintering process issues

The core of the quality of the varistor lies in the quality of its internal chips. Under normal circumstances, the chips need to be sintered for 28 hours, but some low-quality chips are only sintered for 12 hours in order to save power and cost. Using small chips to replace large chips is also a common trick for low-quality varistors. Due to the high price of silver, especially in recent months, the price of silver has risen higher and higher, the silver-plated surface of inferior varistors has become smaller and smaller, and the silver content is also insufficient. Some manufacturers have begun to replace silver with copper. If such a low-quality pressure-sensitive chip is used, the varistor is indeed easily damaged.

2) Too many times of overvoltage protection

A good quality varistor has relatively more overvoltage protection times, and a poor quality one can protect a few times. Regardless of the quality, each varistor has a service life. Too many times of overvoltage protection may cause the varistor to fail.

3) The ambient working temperature is too high

It is a common problem that high ambient temperature of a varistor will cause damage to the varistor. The operating temperature range of an ordinary varistor is -40°C~+85°C. If the temperature is too high, the varistor's life will be greatly shortened.

If you don't pay attention to details in use, it is easy for a varistor to be damaged. In addition to the problems in use, the sintering manufacturing process of the varistor manufacturer is also very important, which is related to the life of the varistor in the future.

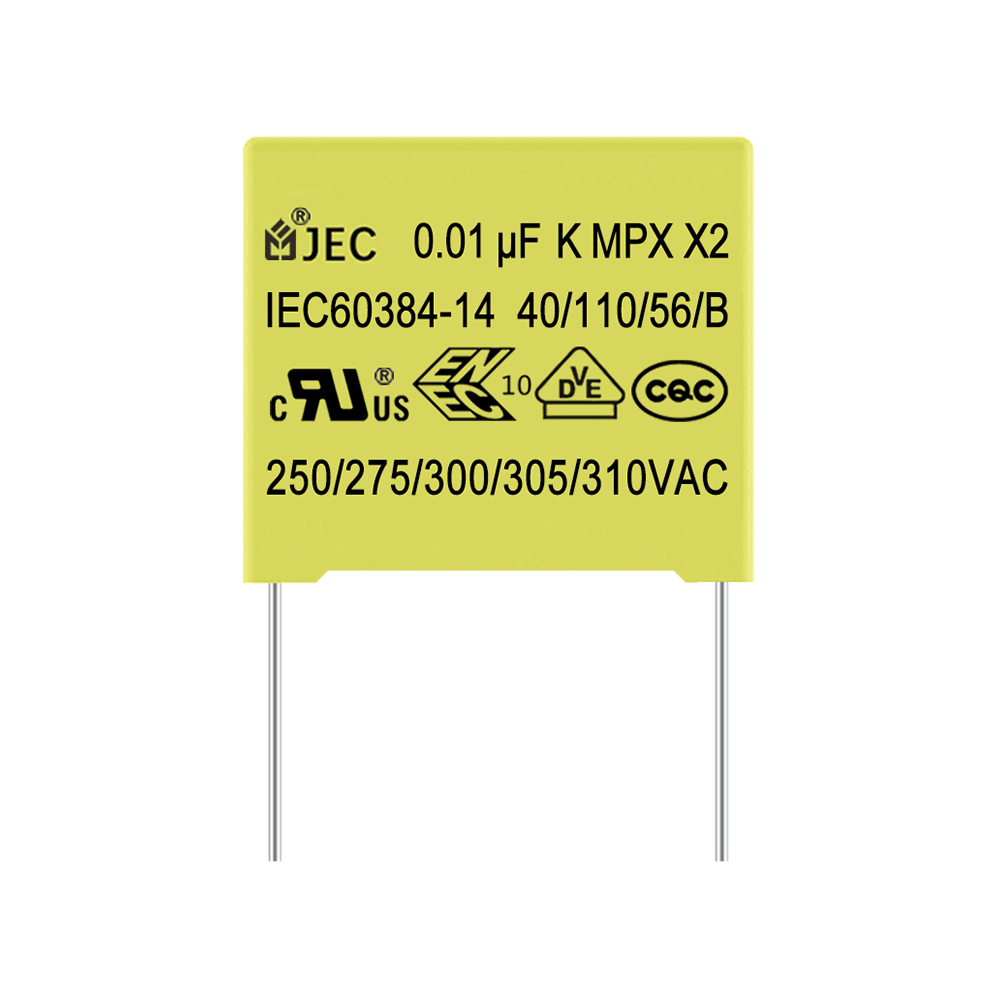

Dongguan Zhixu Electronic Co., Ltd. (also JYH HSU(JEC)) has a full range of varistor and capacitor models with guaranteed quality. JEC has passed ISO9001:2015 quality management system certification; JEC safety capacitors (X capacitors and Y capacitors) and varistors have passed national certifications of the main industrial powers across the world; JEC ceramic capacitors, film capacitors and super capacitors are in compliance with environmental protection indicators. We have over 30 years of manufacturing experience. If you have technical questions or need samples, please contact us.

Previous: Causes of Failure in Film Capacitors

What Will Happen When Safety Capacitors Are Damaged

Sep. 24, 2021

The Aging Phenomenon of Supercapacitors

Sep. 24, 2021

Reasons Why Super Capacitors Are Used

Sep. 24, 2021

+86 181 2299 5593

+86 18122995593

+86 769 8831 3605

Beside Luchong Bridge, Hou Road, Caibai Village, Daojiao Town, Dongguan, Guangdong, China

Navigation